سیستم پوشش اسپری خودکار برای پالپ قالب گذاری شده.

جزئیات محصول:

| محل منبع: | چین |

| نام تجاری: | Osmanuv |

| گواهی: | ISO9001 |

| شماره مدل: | OSM-ZDPT-1320PT |

| سند: | automatic spray coating mac...ne.pdf |

پرداخت:

| مقدار حداقل تعداد سفارش: | 1 ست |

|---|---|

| قیمت: | قابل مذاکره |

| جزئیات بسته بندی: | جعبه چوبی |

| زمان تحویل: | 30 تا 45 روز |

| شرایط پرداخت: | t/t |

| قابلیت ارائه: | مذاکره |

|

اطلاعات تکمیلی |

|||

| ولتاژ: | 220 ولت 50 هرتز | رنگ: | آبی/سبز/سفید |

|---|---|---|---|

| ماده بسته بندی: | چوب | نوع محرک: | برقی |

| ماده روکش: | من | امتیاز فروش کلیدی: | با دقت زیاد |

| لامپ: | از لوله گرمایش کوارتز تایوانی استفاده کنید | اجزای اصلی: | موتور ، موتور |

| برجسته کردن: | automated spray coating system for molded pulp,precision internal coating machine,spray coating machine with warranty,precision internal coating machine,spray coating machine with warranty |

||

توضیحات محصول

سیستم پوشش اسپری خودکار برای پالپ قالب گذاری شده.

1ترکیب خط تولید

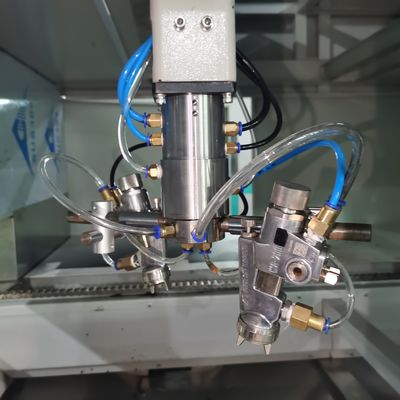

یک سیستم کامل شامل: یک کانویر خودکار، بازوی رباتیک 6 محوری با تفنگ اسپری با دقت بالا، سیستم موقعیت دید، گردش رنگ و سیستم تامین و کابینت کنترل PLC است.

2توضیحات محصول

این سیستم پوشش اسپری خودکار برای استفاده از پوشش های خنک کننده مبتنی بر آب به داخل محصولات پالپ قالب بندی شده شکل پیچیده طراحی شده است.این تضمین می کند که ضخامت فیلم ثابت و پوشش کامل، حتی در ظروف عمیق، به حداکثر رساندن بهره وری مواد و کیفیت محصول.

3پارامترهای فنی

| پارامتر | جزئیات |

|---|---|

| مدل | AS-MP500 (نمونه استاندارد،قابل تنظیم) |

| نوع ربات | ربات صنعتی 6 محوری |

| تکنولوژی اسپری | هواپیمایی بدون کمک هوا با کارایی انتقال بالا |

| یکنواختی پوشش | انحراف ±3٪ |

| دقت موقعیت | ±0.5mm (از طریق سیستم دید) |

| سیستم کنترل | PLC + HMI صفحه لمسی با برنامه ریزی مسیر |

| سرعت کانویر | 0.5 - 3 متر/دقیقه (با ربات هماهنگ) |

4درخواست

ایده آل برای استفاده از موانع رطوبت و چربی در بسته بندی مواد غذایی مانند کاسه ها، صدف ها و سینی های دارای هندسه های پیچیده است.

5. سفارشی سازی

ما پیشنهاد می کنیمکاملا قابل سفارشی سازیسیستم گردش رنگ را می توان برای واسکوزیته های مختلف پوشش سفارشی کرد.

6. ویژگی

-

دقت رباتیک برای پوشش ثابت ۱۰۰%

-

تا 40٪ صرفه جویی در مواد در مقایسه با اسپری دستی

-

موقعیت دهی هدایت شده با چشم، تغییرات ابعاد محصول پالپ را جبران می کند.

-

سیستم رنگ حلقه بسته، لزگی و کیفیت پوشش را حفظ می کند.

7پشتیبانی و خدمات

ما نصب و راه اندازی، آموزش برنامه نویسی مسیر رباتیک و 12 ماه گارانتی را ارائه می دهیم. پشتیبانی فنی 24/7 در دسترس است.

8بسته بندی و حمل و نقل

سیستم به ماژول ها جدا می شود، در جعبه های چوبی ضد آب و هوا با ورودی های فوم سفارشی برای حمل و نقل امن بسته بندی می شود.

9سوالات عمومی

-

س: چگونه اندازه های مختلف محصول را مدیریت می کند؟

-

A: سیستم می تواند چندین مسیر اسپری را ذخیره کند. تغییر سریع از طریق انتخاب دستور العمل در HMI است.قابل تنظیملوازم جانبی با تغییر سریع در دسترس هستند.

-

س: کارایی انتقال چیست؟

-

ج: تکنولوژی اسپری پیشرفته ما بیش از 85٪ بهره وری انتقال را به دست می آورد، کاهش اتلاف مواد و اسپری بیش از حد.