تونل استریلیزاسیون با نور UV با سرعت بالا برای بسته بندی قالب بندی شده سلول غذایی - سیستم خطی حمل کننده

جزئیات محصول:

| محل منبع: | چین |

| نام تجاری: | OSMANUV |

| گواهی: | ISO9001 |

| شماره مدل: | OSM-UVC20-500A |

پرداخت:

| مقدار حداقل تعداد سفارش: | 1 مجموعه |

|---|---|

| قیمت: | قابل مذاکره |

| جزئیات بسته بندی: | جعبه چوبی |

| زمان تحویل: | 30 تا 45 روز |

| شرایط پرداخت: | T/T |

| قابلیت ارائه: | مذاکره |

|

اطلاعات تکمیلی |

|||

| حالت کنترل تایمر: | دستی/اتوماتیک | قدرت: | 1000 وات |

|---|---|---|---|

| سرعت خرد کردن: | قابل تنظیم | منبع نور: | نور UV |

| تایپ کنید: | دستگاه استریلیزاسیون UV | ویژگی های ایمنی: | پوشش محافظ با سوئیچ اینترلاک |

| دقت کنترل تایمر: | ± 1 دقیقه | بسته: | کیس چوبی |

| برجسته کردن: | تونل استریلیزه ی UV برای بسته بندی مواد غذایی,دستگاه تشعشع UV در خط برای قالب دادن پالپ,سیستم استریلیزه ی UV با سرعت بالا,inline UV irradiation machine for pulp molding,high-speed conveyorized UV sterilization system |

||

توضیحات محصول

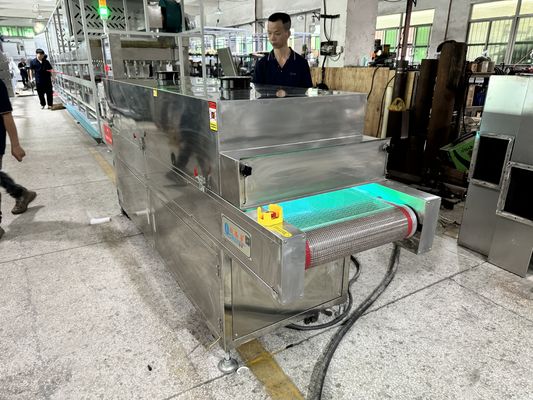

تونل استریلسازی با نور UV با سرعت بالا برای بستهبندی قالبگیری شده خمیر کاغذ درجه مواد غذایی - سیستم خطی نقاله ای

ترکیب خط تولید

این سیستم شامل یک نقاله ورودی، یک محفظه تونل استریلسازی از جنس استیل ضد زنگ با لامپهای UV-C با شدت بالا، یک نقاله خروجی موتوری، یک سیستم اگزوز یکپارچه و یک پنل کنترل PLC قدرتمند با نظارت بلادرنگ است.

توضیحات محصول

تونل استریلسازی UV با سرعت بالا ما برای ضدعفونی مداوم و خطی محصولات قالبگیری شده خمیر کاغذ درجه مواد غذایی مانند سینیها، ظروف و بشقابها طراحی شده است. این دستگاه به طور موثر تا 99.9٪ از میکروارگانیسمها را از بین میبرد و ایمنی محصول را تضمین میکند و ماندگاری را بدون استفاده از مواد شیمیایی یا حرارت که میتواند به مواد حساس آسیب برساند، افزایش میدهد.

پارامترهای فنی

| پارامتر | مشخصات |

|---|---|

| روش استریلسازی | لامپهای میکروبکش UV-C (254 نانومتر) |

| نوع نقاله | کمربند مشبک یا کمربند تخت (قابل تنظیم) |

| عرض کمربند | استاندارد 300 میلیمتر، 500 میلیمتر، 800 میلیمتر (قابل تنظیم) |

| طول تونل | قابل تنظیم برای دستیابی به مقدار D مورد نیاز (دوز) |

| منبع تغذیه | 380 ولت / 50 هرتز / 3 فاز |

| عمر لامپ UV | تقریباً 9000 ساعت |

| سیستم کنترل | PLC با HMI برای کنترل سرعت و شدت |

| ظرفیت تولید | قابل تنظیم بر اساس سرعت نقاله و طول تونل |

کاربرد

ایدهآل برای ادغام در خطوط تولید خودکار برای:

-

سینیها و کلامشلهای قالبگیری شده خمیر کاغذ

-

بشقابها و کاسههای یکبار مصرف

-

کارتنهای تخم مرغ

-

سایر بستهبندیهای مواد غذایی متخلخل و حساس به حرارت

سفارشیسازی

ما سفارشیسازی گستردهای را برای مطابقت با خط تولید شما ارائه میدهیم. ویژگیهای قابل تنظیم کلیدی شامل طول تونل و پیکربندی لامپ برای دستیابی به هدف کاهش لگاریتمی خاص شما، جنس کمربند نقاله و رابطهای ادغام با تجهیزات موجود شما است.

ویژگی

-

راندمان خطی: استریلسازی مداوم و با توان عملیاتی بالا را بدون گلوگاه امکانپذیر میکند.

-

فرآیند بدون مواد شیمیایی و خشک: بدون باقیمانده، بدون رطوبت، ایمن برای محصولات کاغذی و خمیر کاغذ.

-

بهرهوری انرژی: خروجی حرارت کم در مقایسه با روشهای حرارتی، کاهش هزینههای عملیاتی.

-

اینترلاکهای ایمنی: خاموش شدن خودکار هنگام باز شدن تونل برای ایمنی اپراتور.

-

نظارت بلادرنگ: نمایش مداوم شدت UV و سرعت نقاله.

پشتیبانی و خدمات

ما راهنمایی نصب، آموزش اپراتور و موجودی کاملی از مواد مصرفی مانند لامپهای UV ارائه میدهیم. عیبیابی از راه دور و پشتیبانی فنی در دسترس است.

بستهبندی و حمل و نقل

دستگاه به صورت بخشهای مدولار برای نصب آسان حمل میشود. تمام اجزا در جعبههای چوبی ضد آب و هوا برای حمل و نقل بینالمللی ایمن بستهبندی میشوند.

سؤالات متداول

-

سؤال: اثربخشی استریلسازی چقدر است؟

-

پاسخ: میتواند به کاهش >99.9٪ (3-log) باکتریها و کپکهای رایج دست یابد. اثربخشی دقیق قابل تنظیم است و به زمان نوردهی (تابعی از سرعت نقاله و طول تونل) بستگی دارد.

-

-

سؤال: آیا میتواند ارتفاعهای مختلف محصول را تحمل کند؟

-

پاسخ: بله، فضای داخلی تونل قابل تنظیم در هنگام سفارش برای تطبیق با ابعاد محصول خاص شما است.

-

-

سؤال: آیا آسیبی به محصولات وارد میشود؟

-

پاسخ: حداقل. UV-C یک فرآیند سرد است که آن را برای مواد حساس به حرارت مانند خمیر کاغذ ایدهآل میکند.

-